Product Detail

General

- Topside: finished with high-performance “ Lumiflon-based ” Fluorocarbon-FEVE

- 0.5 mm thick aluminum alloy (3105-H14)

- Core material: fire-retardant mineral filled core (FR,A2, A1 )

- Backside: polyester-based wash coating to prevent possible corrosion when installed onto steel structures and high alkalinity cement structures

Dimensions

Thickness: 3 mm, 4 mm and 6 mm

Width: 965, 1,270 and 1,575 mm

(Custom width can be ordered between 914 and 1600 mm)

Length: 2,489 and 3,099 mm

(Custom length can be ordered between 1800 and 7200 mm)

Weight: 6.0 kg /m2 (3 mm), 7.6 kg/m2 (4 mm) , 10.9 kg/m2 (6 mm.)

Color Chart

Coating Warranty

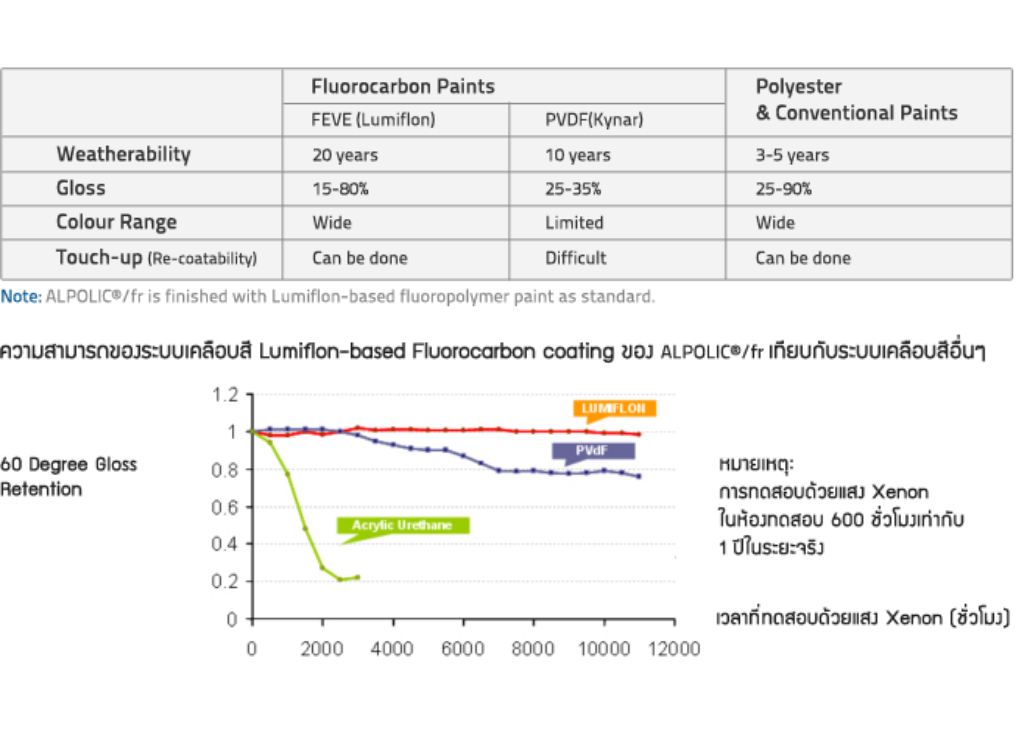

This table shows that the LUMIFLON-based Fluorocarbon (FEVE) system used with ALPOLIC®/fr can maintain the gloss longer than the PVdF system and other color systems It helps the architecture used ALPOLIC color to be longer durable.

Warranty of Panel Delamination

ALPOLIC’s Thermal bonding prevents delamination or peeling in long term use use.The material is made with alloy aluminum type 3105-H14 with the thickness of 0.5mm on both sides with the Continuous In Line Process: Thermo Bonding. The process is without adhesives or other substances to attach in order to prevent delamination. This feature is covered by a 20 year panel warranty.

Installation

Saw Cutting

Running saw and panel saw for woodworking can cut ALPOLIC®/fr panels easily. The carbide tip blade made for aluminum and plastic is recommended.

Shear Cutting

Square shear is the most efficient method for sizing a large quantity of panels. Some shear droop may occur at the cut edge. Appropriate clearance and rake angle is as follows:

|

Panel

Thickness (mm) |

Clearance |

Rake

Angle |

|

3 mm. |

0.04

mm. |

1

degree |

|

4 mm. |

0.04

mm. |

1

degree, 30 arcminute |

|

6 mm. |

0.2

mm. |

2

degree, 30 arcminute |

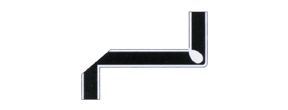

Grooving

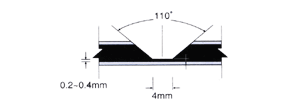

It is important to leave 0.2 to 0.4mm of FR core in U-grooving and 110 degrees of grooving angle is recommended

Method 1 - Router and Trimmer

Use a modified router bit as shown in the left drawing.

Number of teeth : 2-4

Number of rotations : 20,000-30,000 rpm

Feeding speed : 3-5 m/min

Material : Carbide

Method 2 - Groove Cutter

When a large quantity of panels are being processed, groove cutter is more suitable

Material : Carbide tip

Outside diameter : 305 mm.

Number of teeth : 24

Number of rotations : 3,000-5,000 rpm

Feeding speed 5 m/min

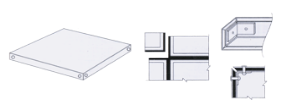

Folding

U-grooved panels can be folded with folding jig, press-brake or plate punch. To ensure a straight line of folded corner, fold the grooved panel on a flat table. It is recommended that the folding operation is held at 10 degrees Celsius or higher temperature to prevent the coating from cracking

Rout- Return System- Normally, 25mm from edge is grooved and folded. After assembling, the corner is sealed with sealant to prevent the corner from water leakage.

Bending with Press Brake

When bending ALPOLIC®/fr panel with press brake, use a top die having the desired radius. The minimum internal bending radius is as follows:

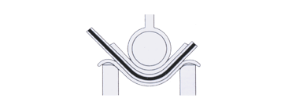

Bending with Three Roll Bender

Three-roll bender enables a larger bending radius than press-brake bending. Groove and slit the curved edge before bending as shown below:

Riveting & Bolting

Use aluminum blind rivet for junction. Fixing work can be done from one direction. Use stainless steel bolt/ nut. When panels are connection with junction hole, the equation of e>2D indicates a suitable relation between the hole diameter (D) and the distance from the hole center to panel end (e), to ensure sufficient tensile strength of the hole.

Welding

One end of ALPOLIC®/fr and ALPOLIC can be connected to another end of ALPOLIC®/fr or ALPOLIC with welding the core by means of hot jet gun. The welding rod is prepared by cutting from slender piece of ALPOLIC®/fr or ALPOLIC panel. Normally, reinforcement is necessary after welding.