Fire Retardant Qualities

ALPOLIC®/fr is a fire-retardant material composed of aluminum trihydroxide- Al(OH)3. This fire-rated core has passed the following tests from various institutes around the world:

Classification of Fire Performance

1. 3. Large level test: non combustibility test of materials and facades in construction

1.1 NFPA 285 is a test from the National Fire Protection Association, USA.

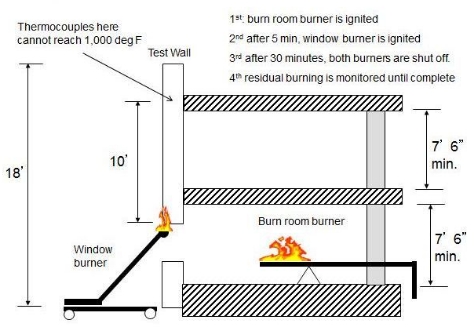

NFPA 285 is a test from National Fire Protection Association, USA.

The wall size for testing is 4.3 meters wide and 5.5 meters high. This test composes of two burners inside and outside which the inner one will be ignited 5 minutes after outside ignition. This test will help determining the fire propagation characteristics of exterior wall assemblies.

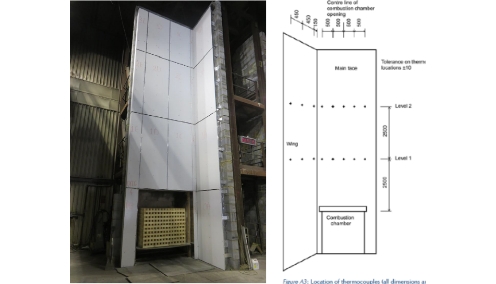

1.2 BS 8414 is the most popular and reliable large scale of non-combustibility test in the world.

After the fire incident at Grenfell, the British government has been focusing on fire-retardancy tests of composite materials more and invented BS 8414. The test is setting up L shaped wall, 2.5 meters and 1.5 meters wide by 8 meters high with a tunnel set up below for ignition. The test determines fire propagation of external cladding in 3 perspectives:

1. External fire spread.

2. Internal fire spread.

3. Mechanical Properties

The specimen will be burned at total heat 4,500 MJ of fire source for 30 minutes. The pass or fail condition is the temperature of the cladding at 5 meter height must not exceed 600 °C. The fire spread must not exceed 8 meters high. ALPOLIC/fr and ALPOLIC A2 have both recognized passed the qualification of BS 8414.

2. Medium Scale tests: non-combustibility test of wall system in construction.

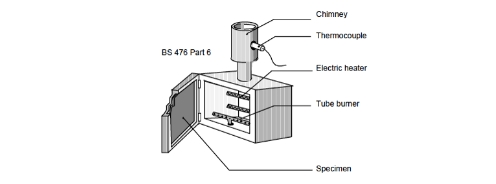

2.1 BS476-Part 6 & Part 7 British standard for fire-retardancy tests on building materials and structures

- Part 6 is the test with 22.8 cm x 22.8 cm aluminum composite, pictured here are two electrical heating elements are placed below a removable steel chimney.

- Part 7 is the test of flame spread on surface by heat radiation.Panel Size 900 x 230 mm with 10 minutes exposure to heat radiation.

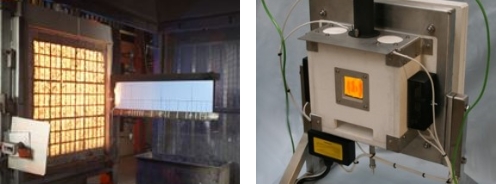

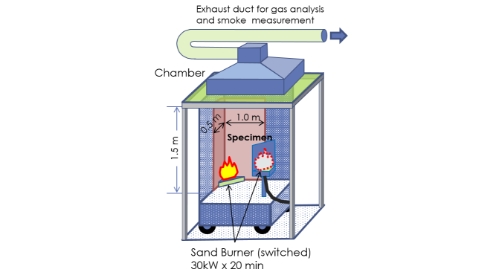

2.2 ISO 13785 – 1 Reaction-to-fire tests for façades used in Czech Republic

The size of specimen tested is 1.2* 2.4 meters and 0.6*2.4 meters. It is tested with a propane burner with the heat up to 100 kilowatts for 30 minutes. Damage of the test specimen must not more than 50 cm from ground.

2.3 EN 13823 European Class Test

Single Burning Item (SBI) method is used here by single burning an item. There is a method of test for determining the reaction to fire behavior of building products (excluding floorings) when exposed to the thermal attack by a single burning item. Mostly used with Aluminum composite with a size of 1m*1.5m. The gas will be released before the test on one side for heat measurement, then additional heat release from the composite. This test is for European Class A2, B, C, D.

3. Small scale tests: material test

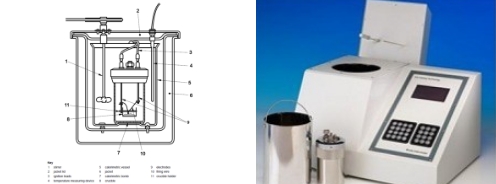

3.1 ISO 1182 Reaction to fire tests for materials— Non-combustibility test

A test specimen will be placed inside a cylindrical furnace tube at 750 °C for 30 minutes or more subject to each condition. The conditions used follow the Euro class A1 which will increase temperature 30°C to 780°C. For A2 product test, the temperature will be increased by 50°C or more. The mass loss of the test specimen is calculated after the test is completed.

3.2. ISO 1716 Reaction to fire tests for materials — Determination of the gross heat of combustion (calorific value)

It is to determine the gross heat of combustion in the laboratory in order to be classified into Euro class accordingly.

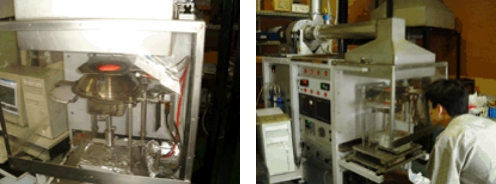

3.3 ISO 5660-1 is the Cone Calorimeter Test

which is used in building control act in fire control laws in Japan to see if the filling is combustible or not by the product can be certified as non-combustible materials by this test using a 10 x 10 cm sample to heat from a Cone Heater that emits 50 kilowatts per square meter and the temperature is around 650 degrees celsius (The near temperature of aluminium melting point).